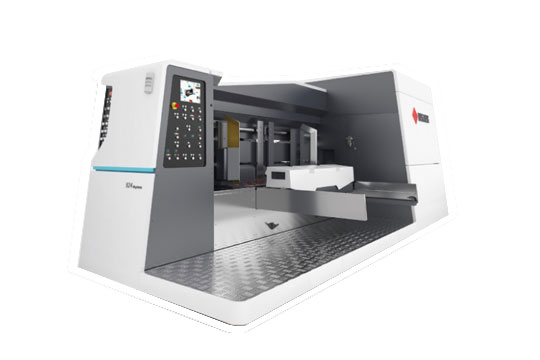

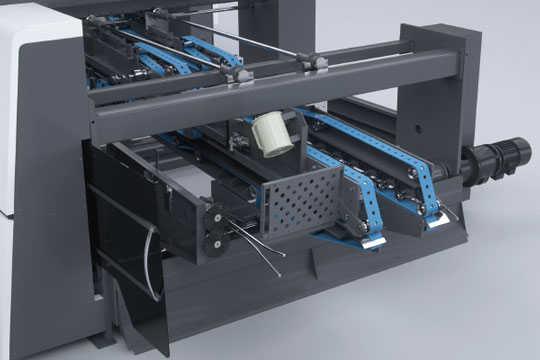

★ Precision ball screw with linear guide rail, synchronized upper and lower knives, without cutting

★ Suspended cutter head structure, slotting without burrs or paper picking, with good wire pressing and molding

★ Double blade slotting mode, reducing blade disassembly, and completing order adjustment within 2 minutes

The pre pressing pressure of the trimming knife and corner cutting knife can be adjusted separately, resulting in a beautiful box effect and better adaptability to various needs

★ Imported cross directional linkage system from Japan, accurate and stable displacement